Plant Condition Monitoring

2022-10-30

Businesses in the material processing industry require robust solutions for critical production lines and harsh environments. Process industry companies, such as mining companies, want to take the next optimization steps and improve their use of resources by early detection of deviations. If deviations are not detected quickly, there are risks of breakdowns and an accumulation of waste that must be re-processed. An unplanned stop also poses a threat to the workers.

Production availability is one of the most crucial performance indicators

While there are many parameters to describe overall site performance, tracking production availability and the percentage of production time utilized is crucial. Unplanned stops, including both breakdowns and maintenance, lead to costly downtime. Real-time lidar monitoring can help maintain high production availability by providing early detection of deviations and preventing unplanned stops and costly breakdowns.

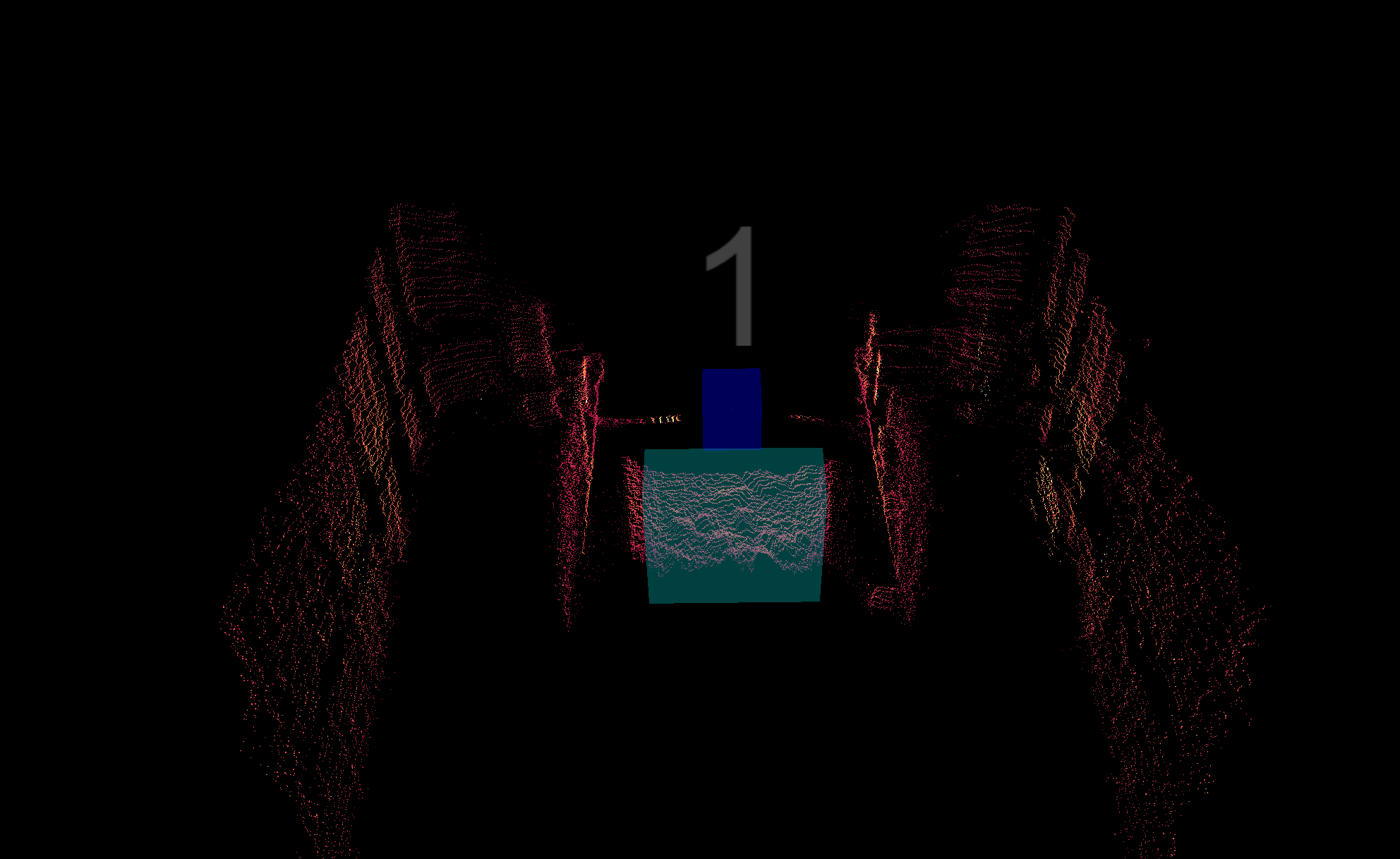

Traditional monitoring methods, such as video cameras and measurement tools, have limitations in terms of accuracy and data overload for operators. Lidar technology overcomes these limitations by providing precise, actionable 3D data in real-time. This allows for a more efficient and accurate monitoring system, reducing the need for manual intervention and enabling operators to make informed decisions quickly.

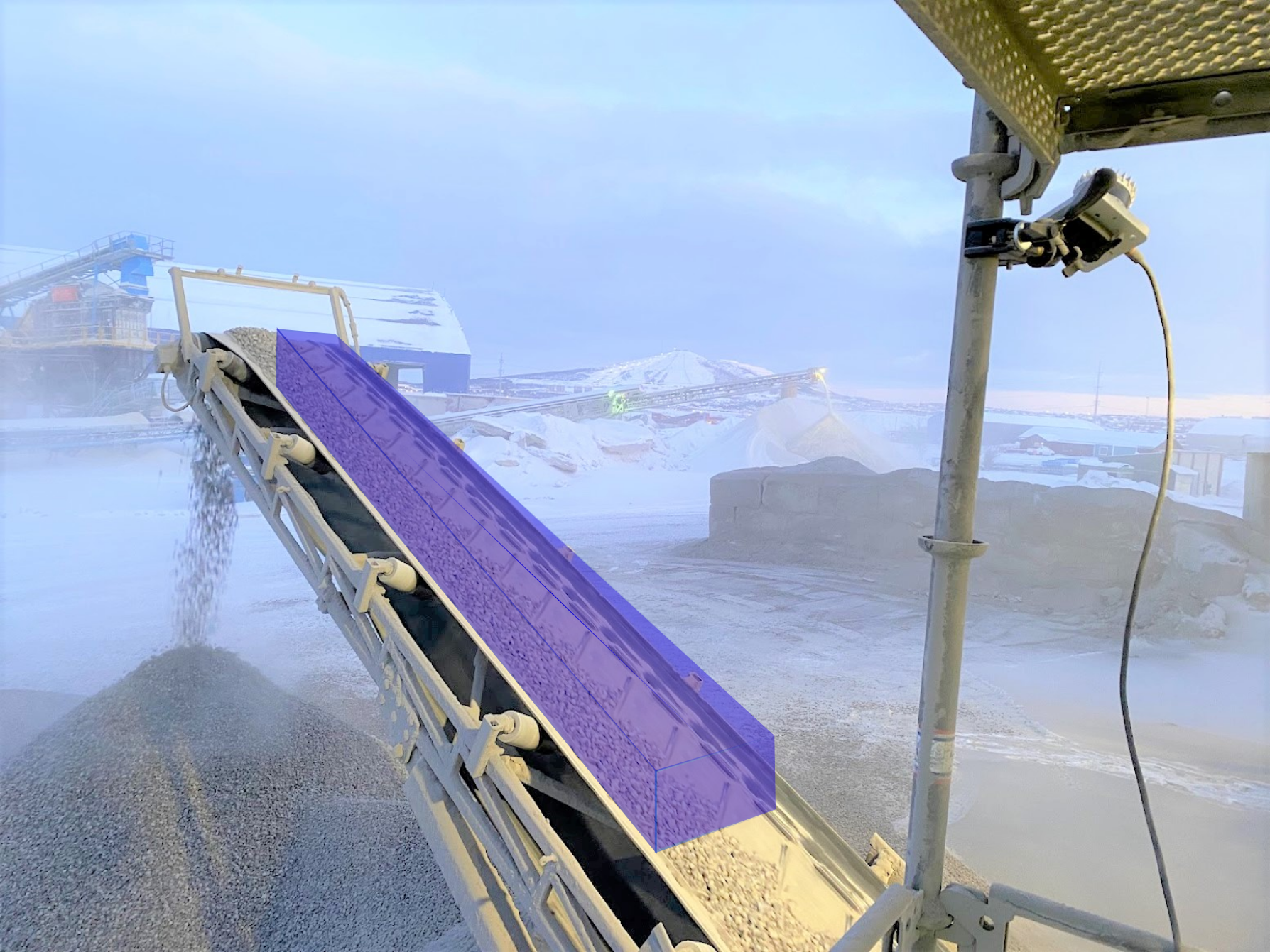

Lidar technology analyzes material and production flow in real-time and 3D, offering unparalleled opportunities to detect deviations earlier and with greater detail than traditional methods. These advanced features can be applied directly to conveyor belt monitoring, enabling operators to identify potential issues before they escalate

Start to track these parameters to prevent downtime

To prevent downtime, Lidar sensors can be used to monitor a range of parameters, such as volumes, shapes, and distances. By analyzing the movement of the conveyor belt and the material it transports, early warning signs of wear and tear, misalignments, and potential blockages can be detected, allowing for timely maintenance before damage occurs.

Conveyor belts are often the cause of downtime, accidents, and loss of productivity.

Real-time lidar monitoring can help prevent these issues by detecting potential problems early, reducing the risk of accidents, minimizing downtime, and extending the life of conveyor belts by providing the early warnings needed to take the right actions before damage occurs.

Lidar sensors offer additional safety benefits by monitoring both the belt and the surrounding environment without breaching GDPR laws. Industrial customers can set up virtual safety zones close to the conveyor belts, enhancing safety in two ways:

1) Increased control of production allows workers to remain in safe environments during operation

2) If workers need to be present, machinery can be stopped automatically when dangerous movements are detected within the safety zones.